Cam clamps

Cam clamps generate a clamping force on a movable clamping surface using a cam mechanism and are connected to the work plate or holder with pins or screws. Variants with an end lock concentrate clamping force at the end or edge of workpieces, while those with a middle lock act in central areas, particularly for longer workpieces. Renowned for their ability to apply significant clamping force, cam clamps serve a broad range of industries, from mechanical to automotive engineering.

High quality cam clamps for precise clamping

What is a cam clamp?

Advantages and application areas of cam clamps

Our range at a glance

Cam clamps from norelem

High quality cam clamps for precise clamping

A cam clamp is a mechanical clamping tool that is widely used in manufacturing and assembly. It is characterised by its ease of use and high efficiency, making it an indispensable tool in many industrial and craft applications.

A typical cam clamp consists of several main components:

- Baseplate: The base that is attached to the work table or a fixture.

- Cam: The main component that provides the clamping force.

- Lever or grip: Used to operate the cam.

- Thrust pad: Grips the workpiece and holds it in position.

- Adjustment screw: Provides fine adjustment of the clamping force and lamping position.

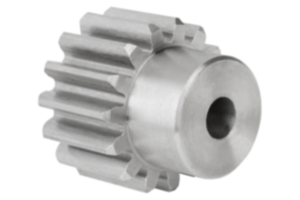

The core of the clamp is the cam, a rotating body with an uneven diameter. This cam is actuated by a lever or grip, causing it to rotate and exert a clamping force on the workpiece.

What is a cam clamp?

Cam clamps are standard parts that clamp workpieces quickly and securely. They are indispensable in many industrial applications as they offer reliable clamping force and are simultaneously easy to operate.

These special clamping devices work on the principle of leverage and eccentric rotation. The cam mechanism generates a variable clamping force depending on how far the cam is rotated.

Here is a detailed description of how an cam clamp works:

Start position: When not clamping, the lever is in a neutral position and the clamping pad is loose.

Rotational movement of the cam: When the lever is actuated, the cam rotates. As the cam has an uneven diameter, the distance between the axis of rotation of the cam and the contact face of the clamping pad increases during rotation.

Generating the clamping force: Rotating the cam reduces the distance to the clamping pad to the workpiece surface, pressing the clamping pad against the workpiece. This movement generates a strong clamping force that holds the workpiece securely in place.

Clamping the workpiece: As soon as the lever is fully actuated, the cam remains in position and holds the workpiece firmly. The clamping force can be precisely controlled by the shape of the cam. The clamped workpiece can be machined during this phase.

Releasing the workpiece: To release the workpiece, the lever is rotated in the opposite direction. This reduces the distance between the axis of rotation of the cam and the contact face of the clamping pad, which reduces the clamping force and releases the workpiece.

Cam clamps with centre lock and end lock

The clamps are available in various styles, which differ in the way they generate and distribute the clamping force. The two main types are cam clamps with end lock and with centre lock.

Cam clamps with centre lock exert the clamping force in the centre of the clamping path. This means that the maximum clamping force is not attained at the end, but when the lever is in the middle position. The clamp with centre lock is used when a uniform clamping force is required over a area range.

Cam clamps with end lock exert the clamping force at the end of the clamping path. This means that the maximum clamping force is attained when the lever has reached the end of its travel. The clamp with end lock is often used when a high clamping force needs to be exerted on a small contact area.

Direct comparison of the two cam clamps

Features | Cam clamp with end lock | Cam clamp with centre lock |

Clamping force distribution | Maximum clamping force at the end of the clamping travel | Maximum clamping force in the centre of the clamping travel |

Applications | High clamping force on small areas | Uniform clamping force over large areas |

Advantages | High maximum clamping force | Uniform and controlled clamping force |

Disadavantages | Uneven clamping force distribution | Limited maximum clamping force |

Advantages and application areas of cam clamps

Cam clamps offer a number of advantages that make them indispensable in many industrial and trade applications. We have summarised some of the key benefits for you:

- High clamping force: Cam clamps can exert a strong clamping force that holds the workpiece securely in position. This force is generated by the rotary movement of the cam and can be precisely controlled.

- Quick and simple operation: The lever mechanism makes cam clamps quick and easy to operate. Clamping and releasing the workpiece requires only a few hand movements, which significantly speeds up work processes and increases efficiency. The cam clamp excels with its rapid and torque-free clamping.

- Precise clamping force control: The eccentric movement enables fine control of the clamping force. This is particularly important when machining delicate workpieces where uniform and controlled clamping is required.

- Versatile: Cam clamps are versatile and can be adapted to different workpiece sizes and shapes. They are available in various designs and sizes, which enables them to be used in a wide range of applications.

- Durability: Our cam clamps are made from robust materials that guarantee a long service life. This makes them a cost-effective solution for long-term applications.

- Repeat accuracy: Cam clamps offer high repeat accuracy when clamping and releasing workpieces. This is particularly important in batch production, where consistent results are required.

- Reduced setup times: The quick and easy handling of cam clamps significantly reduces set-up times. This means that less time is needed to set up the tools and more time is available for the actual machining process.

No wonder that the cam clamp plays an important role in various industrial applications. In the woodworking industry, cam clamps are often used to securely hold pieces of wood in place. This is particularly important for work such as sawing, sanding, routing and drilling. In metalworking, on the other hand, cam clamps are used to hold metal parts in place during welding, shearing or drilling.

By using cam clamps, craftsmen can make precise and rapid cuts and drill holes, resulting in higher quality end products. The rapid clamp and release function also saves time and increases productivity. From woodworking and metalworking to assembly and aerospace - the cam clamp is an indispensable tool that significantly improves efficiency and performance in industry.

Our range at a glance

In addition to cam clamps, norelem offers a wide range of other products. The products in this category belong thematically to the standard part cam clamps. Here is a brief overview of the rest of the range.

Hinge pins from norelem are made from high-quality steel or stainless steel and are tempered to ensure high strength and durability. The steel version is tempered to 1000 - 1200 N/mm² and black oxidised, the stainless steel version is tempered to 900 - 1050 N/mm² and left bright. These hinge pins are precision-ground and offer high dimensional accuracy, making them ideal as spare parts. They are mainly recommended for use with cam levers and eye bolts and come with matching circlips.

Our spacer bolts are made from 1.1181 Q&T steel and are characterised by their robust and durable design. These bolts are tempered and black oxidised, which gives them excellent surface hardness and corrosion resistance. Spacer bolts are essential components in the machine and plant construction industry and are used to ensure precise distances between components.

The cam levers are made from 1.7220 Q&T steel and have a plastic ball grip for easy handling. The levers are tempered and black oxidised to ensure a long service life and high resistance. The cam levers have a logarithmic spiral cam, which offers consistent clamping properties over the entire working range. Matching hinge pins are also available in the range, enabling seamless integration into various applications.

The cam levers are available in single and double versions.

The spiral cam is made from case-hardening steel 1.7131 (sectional steel), is fully deburred and the spiral start and end is marked. It is used wherever self-locking clamping or securing is required. It is operated mechanically, pneumatically or hydraulically via a central shaft or a side-mounted lever. The self-locking effect is maintained even in the event of a pressure drop, which significantly increases operational safety with pneumatic and hydraulic clamping.

Cam clamps from norelem

norelem is an internationally renowned company specialising in the sale of standard components for machine and plant construction. With its broad product range, including clamping technology, linear technology, operating parts and standard elements, norelem offers comprehensive solutions for a wide variety of industrial requirements. We are known for our high product quality, innovative solutions and reliable delivery.

If you need cam clamps, we are your ideal choice. One of the main reasons why you should buy cam clamps from norelem is the outstanding quality of the products. Another advantage of buying from us is the constant availability and rapid delivery of the products. Thanks to our extensive stocks, we can guarantee fast delivery. This minimises downtimes and ensures that your production processes run smoothly. In addition, norelem offers a wide range of cam clamps in various designs and sizes so that you can find exactly the right tools for your specific requirements.