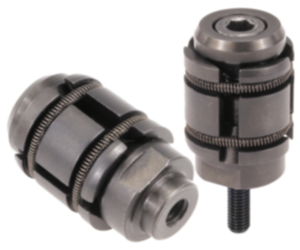

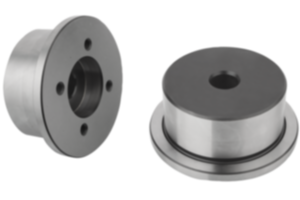

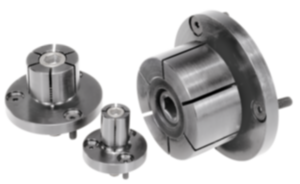

Machinable Collet System

pneumatic

QT steel

nickel-plated

- Pneumatic actuation

- For clamping workpieces with asymmetrical contours

- For mounting in own fixtures and clamping systems

- High repeat accuracy

Sales unit

879,67 €

plus sales tax

norelem.product.details.availability.details.offline

Added to your shopping cart

Designation

Machinable Collet System

Form

A

Version 1

pneumatic

Body material

QT steel

Body colour

nickel-plated

D=Diameter

65

FS=Retaining force N

4000

H=Height

90

P=Operating pressure mpa

0,5

D1

110

D2

19

D3

98

D4

M08

D5

M04

D6

18

H1

80

H2

10

H3

72

H4

65

H5

4

L

49

L1

45

MM3000_002

03166-065025

PL PNEUMATIK

TRUE

Description

Material

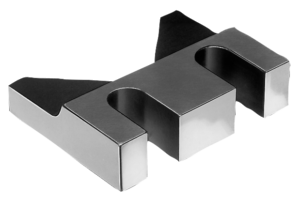

Chuck high-carbon steel, nickel-plated.

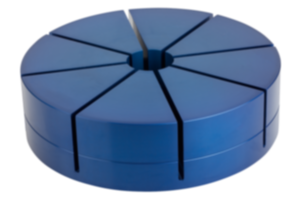

Collet high-strength aluminium, blue anodised.

Collet high-strength aluminium, blue anodised.

Note

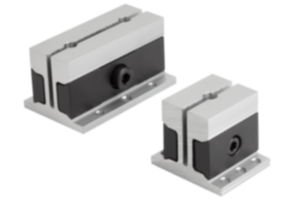

The pneumatic collet system consists of a chuck and a machinable collet.

The chuck can be screwed onto fixtures according to the mounting dimensions.

Clamping procedure:

The collet is opened by applying compressed air to the ”open” port.

The collet is closed (for clamping) by applying compressed air to the ”close” port.

The pneumatic connections can be screwed on either from below or from the side. If the air is connected from below, the side ports must be closed.

Machining the collet for external clamping:

The negative form of the workpiece to be clamped is machined into the collet. Free-form and asymmetrical contours are possible.

Different workpieces can be clamped quickly and securely by simply exchanging the collet.

The collet can be milled down to height H2. This enables multiple workpiece contours to be machined into one collet.

Repeat accuracy for workpiece: +/-0.03

Repeat accuracy after replacing the collet +/- 0.02

The collet radial clamping travel is 0.15 mm per clamping segment.

To prevent damage the collet should not be tightened without a workpiece or clamping ring in place.

The operating air pressure should lay between 0.45 - 0.55 MPa.

The clamping forces indicated are based on 0.5 MPa.

The chuck can be screwed onto fixtures according to the mounting dimensions.

Clamping procedure:

The collet is opened by applying compressed air to the ”open” port.

The collet is closed (for clamping) by applying compressed air to the ”close” port.

The pneumatic connections can be screwed on either from below or from the side. If the air is connected from below, the side ports must be closed.

Machining the collet for external clamping:

The negative form of the workpiece to be clamped is machined into the collet. Free-form and asymmetrical contours are possible.

Different workpieces can be clamped quickly and securely by simply exchanging the collet.

The collet can be milled down to height H2. This enables multiple workpiece contours to be machined into one collet.

Repeat accuracy for workpiece: +/-0.03

Repeat accuracy after replacing the collet +/- 0.02

The collet radial clamping travel is 0.15 mm per clamping segment.

To prevent damage the collet should not be tightened without a workpiece or clamping ring in place.

The operating air pressure should lay between 0.45 - 0.55 MPa.

The clamping forces indicated are based on 0.5 MPa.

Accessory

Clamping ring for machining the contour.

O-ring.

Locating pin.

Clamping screw for collet.

O-ring.

Locating pin.

Clamping screw for collet.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.