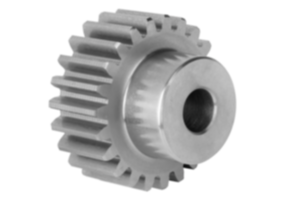

Material

Steel 1.0503 (C45).

Version

Milled toothing, straight teeth.

Engagement angle 20°, bright.

Engagement angle 20°, bright.

Show more

Show less

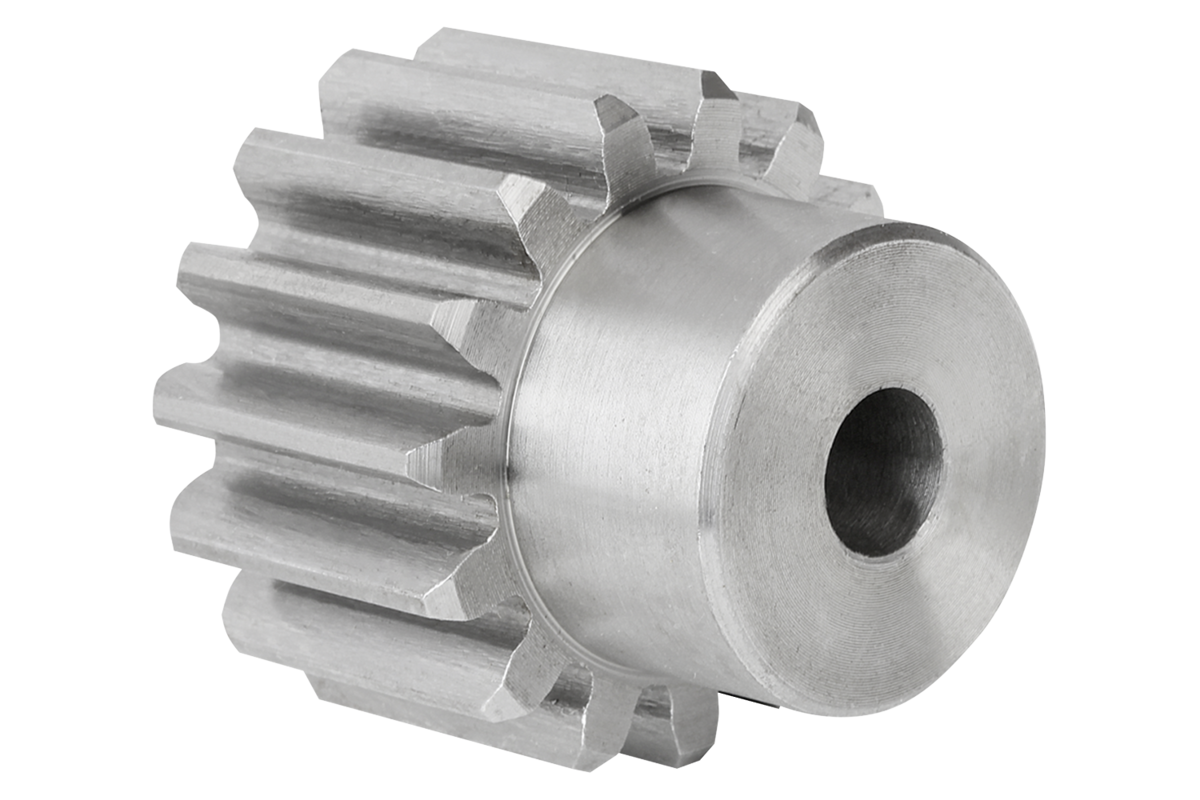

Steel spur gears, module 4, milled toothing, straight-tooth design, 20° engagement angle, Form A, with hub

from

29,60 €

plus sales tax

plus shipping costs

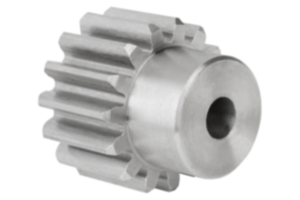

Steel spur gears, module 4, milled toothing, straight-tooth design, 20° engagement angle, Form B, without hub

from

73,39 €

plus sales tax

plus shipping costs

Description

Material

Steel 1.0503 (C45).

Version

Milled toothing, straight teeth.

Engagement angle 20°, bright.

Engagement angle 20°, bright.

Note

Up to 36 teeth with hub one side, from 38 teeth supplied as disc form. The spur gears have a centre bore or pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the spur gears are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter.

Drawing reference

Form A: with hub

Form B: without hub

Form B: without hub

Gear wheels

In practice, spur gears are mainly used for lifting and lowering loads. They ensure positive-locking and slip-free transmission of forces, even with alternating directions of rotation.

The diameters can be selected from 14-387 mm, the tooth width between 15-30 mm. To simplify assembly, the gear wheels can be fitted with a hub on request.

The diameters can be selected from 14-387 mm, the tooth width between 15-30 mm. To simplify assembly, the gear wheels can be fitted with a hub on request.