norelem moves – 23000

The product group 23000 from norelem can be subdivided into eight categories:

- Couplings

- Shrink discs

- Universal joints

- Quick-fit couplings

- Plain bearing

- Rolling bearings

- Seals

- Clamping sets (shaft-hub)

Couplings

Couplings are frequently used in the areas of material handling, the packaging industry, machine construction and the automobile industry.

If, for example, two aligned shafts are to be connected to each other, the rigid coupling is used. It achieves greater stability at high speeds (4000 rpm) and stands out positively under difficult conditions, such as temperatures from -40°C to + 175 C°.

The norelem range includes various types of coupling, in addition to rigid couplings, the elastomer dog coupling and the beam coupling, the Oldham-type coupling and the metal bellows coupling are also available. The material of the coupling types ranges from aluminium to stainless steel and steel.

The following product versions are available in the category "Couplings":

- Slit

- Two-piece

- Clamping with grub screw

- with detachable clamp hubs

- with conical hub and shaft collar

- with radial clamping hub

Shrink discs

The bodies of the norelem shrink discs consist of stainless steel or steel. Shrink discs are attached to the outside of the hub and then exert a compressive force between the shaft and hub. Available with inside diameters from 14-80 mm, the shrink discs can be used to mount e.g. hollow shafts or hubs on shafts.

Assembling the shrink disc

To fit a shrink disc, it is first necessary to remove the existing transport lock. Once the shaft and the hub (inside and outside) have been cleaned and lightly oiled, the shrink disc can be slid onto the hub.

It is important not to use MoS2 or grease when oiling.

The shrink disc hub unit can now be moved onto the shaft and positioned.

The clamping screws can now be lightly tightened by hand one after the other, after which they must be tightened to the specified tightening torque in several stages using a torque wrench.

norelem recommends the following procedure:

1nd setup ca. 33% MS

2nd setup ca. 66% MS

3rd setup 100% MS

Universal joints

Universal joints are used to connect two shafts or axles. They are often used in machines or other mechanical applications to enable movement between two components. They are particularly useful where components are not arranged in a straight line but require a curved or oblique movement. Universal joints can compensate for large angular displacements but can also be used to convert a rotary motion (e.g. that of a motor) into a linear motion.

They are available in various sizes and designs. norelem offers steel and stainless steel universal joints in its range.

In addition to simple DIN 808 universal joints, the range also includes the following products:

- Cardan double joints with needle bearing DIN 808

- Telescopic cardan shafts

- Cardan double joints with plain bearing DIN 808

- Single and double protective rubber sleeves for universal and cardan joints

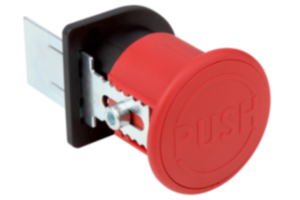

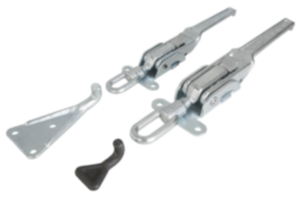

Quick-fit couplings

Quick-fit couplings are used to quickly and easily connect (and disconnect) two parts. Due to the convenient and efficient way of connecting two parts together without the use of tools or other aids, Quick-fit couplings are frequently used in the industrial, automobile and aerospace sectors.

Quick-fit couplings are available in various sizes and forms and can be used for different applications.

Plain bearing

Plain bearing are used everywhere these days, be it in household appliances or industrial plants. They absorb loads in the form of sliding or rotary movements while in contact with a moving part.

Plain bearings are usually cylindrical in shape, contain no moving parts and are also called bushes. The plain bearings from norelem are made from bronze, ceramic, sintered bronze or steel.

The norelem product range extends as follows:

Rolling bearings

Rolling bearings support and protect moving parts in machines and other applications. These mechanical bearings facilitate movements through a rolling motion. The reduced friction between the machine parts reduces wear and increases the service life of the machine and its individual components. Roller bearings enable low-friction and precise rotary movements and can withstand enormous speeds.

The following versions are part of the norelem range:

- Rolling bearings with cylindrical bore

- Single-row or double-row rolling bearings

- Single-acting rolling bearings

Seals

The product selection of Seals comprises two products.

The O-ring are universally applicable and help to seal against liquid and gaseous elements. Regardless of whether a radial or axial seal is required, depending on the installation of the O-ring, both can be achieved.

Rotary shaft lip seals prevent gas and liquids from escaping from equipment, such as machines. In combination with a bearing or shaft, they create a secure seal. The sealing parts of the rotary shaft lip seals are made of NBR elastomer. The tension spring and the stiffening ring are made of steel.

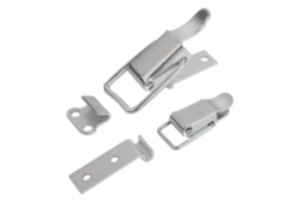

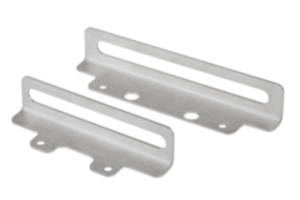

Clamping sets (shaft-hub)

KL couplings are mechanical couplings used to join shafts and hubs. They are often used in machines, motors or other applications to create a permanent link between components.

With 14 product families, this category is the largest in group 23000 of systems and components for machine and plant construction.

The KL couplings from norelem are made of various materials such as stainless steel, grey cast iron and steel and include KL couplings and taper clamping bushes as well as a shaft-hub clamping set.