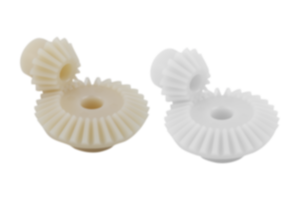

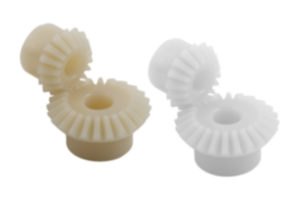

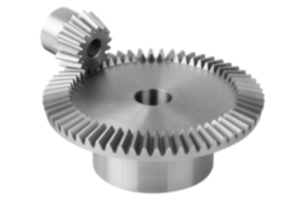

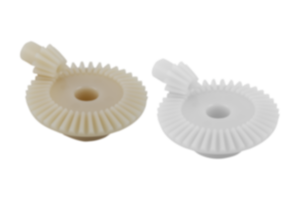

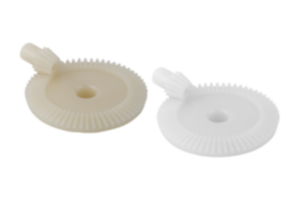

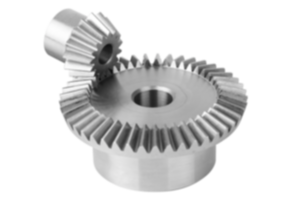

Bevel Gear

straight

polyacetal

- High hardness

- Lower coefficient of friction

- Long service life

- High security against tooth breakage

Sales unit

3,09 €

plus sales tax

norelem.product.details.availability.details.offline

Added to your shopping cart

Designation

Bevel Gear

Version 1

straight

Body material

polyacetal

D1=Pitch circle diameter

25

D3=Thread

8

L=Width

28,7

N=No. of teeth

10

U=Transmission ratio

1:3

A

52,4

B

15,2

D

29,6

D2

18,8

L1

13

L2

-

Module

2,5

Torque Ncm

119,3

Description

Material

Polyacetal (POM) or polyketone (PK).

Version

Injection moulded, straight teeth. Engagement angle 20°. Axis angle = 90°.

Machined bores from module 1.5.

Polyacetal, white.

Polyketone, ivory tone.

Machined bores from module 1.5.

Polyacetal, white.

Polyketone, ivory tone.

Note

Polyacetal: Standard material with high hardness grade and low coefficient of friction.

Polyketone: Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties.

Can be used under water and other media.

Injection moulded gear wheels may have internal manufacture-related cavities. These may become visible during drilling or broaching. They do not impair the function.

Bevel gear wheels are supplied as single components. To obtain a pair of bevel gear wheels, please order the specified mating gear as well.

Polyketone: Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties.

Can be used under water and other media.

Injection moulded gear wheels may have internal manufacture-related cavities. These may become visible during drilling or broaching. They do not impair the function.

Bevel gear wheels are supplied as single components. To obtain a pair of bevel gear wheels, please order the specified mating gear as well.

Temperature range

-40 °C to +140 °C (taking amount and duration of load into account).

Attention

The torques specified in the tables relate exclusively to the toothing. The shaft diameter, key size, etc. are not taken into account. The permissible load calculations are based on the basic principles of the pitting load capacity of the tooth flanks as well as the occurring tooth root stress. The respective permissible load of a gear wheel depends on so many different factors that the values specified can only be reference values meant to make selection easier. The torque specifications relate to a single tooth. The overlap, which is essential for determining the transmissible torque, occurs depending on the pitch diameter, gear wheel pairing, etc. In the simplest straight tooth cases, an overlap ratio of 1.1 to 1.25 is normal. To increase the overlap, a higher number of teeth with smaller modules is used. A good profile overlap can minimise damage such as pitting.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.